For procedures, see your mechanical laboratory manual.

Title: Automat Spur Gear Models A1 - A5

Aim

To examine the working of various types of toothed gearing through Automat

models.

Theory

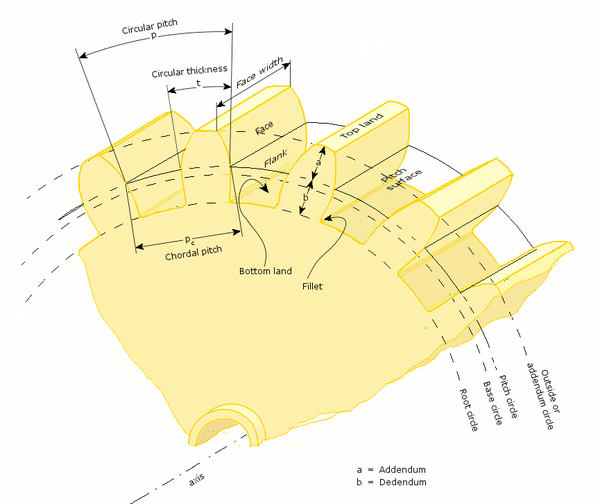

Spur gears or straight-cut gears are the simplest types of gear. Spur gears

have teeth that protrude outward from the perimeter of the gear. They are

mounted on parallel axes and can be used to create a wide range of gear

ratios. One drawback of this mechanism is that the collisions between each

tooth cause a potentially objectionable noise since the entirety of each

tooth meshes at once.

The teeth of a spur gear have an involute profile and mesh one tooth at a

time. The involute form means that spur gears only produce radial forces (no

axial forces), but the method of tooth meshing causes high stress on the

gear teeth and high noise production. Because of this, spur gears are

typically used for lower-speed applications, although they can be used at

almost any speed.

Idler Gears

An idler gear is a gear wheel that is inserted between two or more other

gear wheels. The purpose of an idler gear can be two-fold. Firstly, the

idler gear will change the direction of rotation of the output shaft.

Secondly, an idler gear can assist to reduce the size of the input/output

gears whilst maintaining the spacing of the shafts.

Compound Gears

A compound gear is several gears fixed together. Consequently, they rotate

at the same speed. An example can be seen below. The gears that make up a

compound gear usually differ in size and have a different number of teeth.

This is useful if there is a need to speed up or slow down the final

output.

Worm Gears

A worm gear is a gear consisting of a shaft with a spiral thread that

engages with and drives a toothed wheel. Worm gears are an old style of

gear and a version of one of the six simple machines. Basically, a worm

gear is a screw butted up against what looks like a standard spur gear

with slightly angled and curved teeth.

It changes the rotational movement by 90 degrees, and the plane of

movement also changes due to the position of the worm on the worm wheel

(or simply "the wheel"). They are typically comprised of a steel worm

and a brass wheel.

Bevel Gears

Bevel gears are gears where the axes of the two shafts intersect and the

tooth-bearing faces of the gears themselves are conically shaped. Bevel

gears are most often mounted on shafts that are 90 degrees apart but can

be designed to work at other angles as well. The pitch surface of bevel

gears is a cone.

Bevel gears transmit motion between angular or intersecting shafts,

while spur gears transmit motion between parallel shafts.

There are several types of bevel gears available differentiated mainly

by their tooth design. Some of the more common types of bevel gears

include straight, spiral, and Zerol® bevel gears.

References

- Spur gears, motioncontroltips.com.

- Spur gear, wikipedia.org.

- The bevel gear, wikipedia.org.

- Bevel Gears, sciencedirect.com.

- Peter R.N. Childs, in Mechanical Design Engineering Handbook (Second Edition), 2019.

- Worm Gears Explained, machinerylubrication.com.

- Compound Gears, technologystudent.com.

- Idler-wheel, wikipedia.org.

- Gear Mechanisms, creativemechanisms.com.

- Gear, wikipedia.org.

- Understanding Gears, thomasnet.com.

2 Comments

👍

ReplyDeletenice blog!!

ReplyDelete